The Realistic 12-675 Tech Page

This is a project 30 years in the making. For many years in my teenage, college, and early single days my primary DX portable was a Radio Shack Realistic 12-675. I attempted a restoration project 30 years ago, but the case of the radio - exposed repeatedly to humidity (no doubt) fell to pieces and disintegrated, leaving me with an impossible restoration project. I preserved the PC board, and actually used it to create a "Frankenradio" project a year ago. I got really lucky on eBay and found a 12-675. I got even luckier winning the auction by 1 cent! So - for those of you that own this venerable classic, I proudly present this technical page, with a bit of restoration and modifications thrown in.

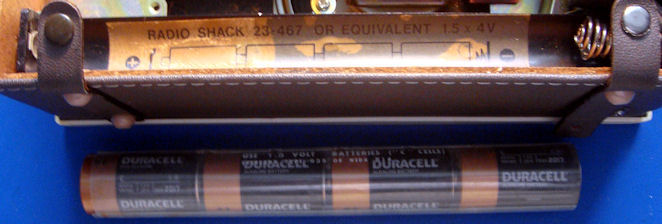

One of the things that made this radio so fun for hobbyists was the easy access to the interior for alignment and modifications:

Let's get started with a tear down.

The chassis is held to the case by 6 screws, which screw into stand-offs.

The third screw is hidden under the label.

At this point, the chassis is loose and can be flipped to the side to allow access to the rear of the board.

I did contemplate doing instructions to remove the board from the chassis, but there would be enough effort involved for little additional board access that I elected not to. In addition, the dial stringing is complex enough that you do not want to risk it. See the unique two level cam:

This is a rather clever trick that allows the use of a small pulley on the tuning capacitor and yet have a wide dial. Very slick!

Since this is also a restoration article, I note that there is a small schematic on the inside of the case. It doesn't have component values, but is nonetheless useful. If, however, it can be restored. The schematic has faded to brown, and the original adhesive obvisously let loose at some point, leading a previous restorer to use a different adhesive, which bleached the brown paper a bit:

In order to make this readable, I first need to get it off the inside of the cabinet. I used a scraper:

This allowed me to mount the schematic on a piece of white paper. I then scanned it with a high resolution scanner, and used a graphics program to take all the brown out. I then printed it on photographic paper for later re-installation inside the cabinet. I have included the schematic below this restoration / disassembly procedure.

The next steps require a lot of dexterity, working in tight spaces. You are probably after getting to the rear of the PC board. Stop while you are ahead! I had to go on, since I was going to do a complete tear down to clean and restore everything. If that is what you are doing, continue on. This is the tight area:

Also in the same area is the earphone jack. It is held with the traditional circular nut inside a small plastic well. The headphone jack itself is retained with a large flat washer. If you convert to a stereo jack like I did, things will be a bit problematic as I describe later.

At this point, you have all the electronics free and can removed them from the case interior. The rest of this article describes a case teardown.

At this point, the front panel is loose and can be removed from the cabinet.

Do not make a mistake that I made. It might look like you can remove the wooden handle pieces by unscrewing three screws:

But you cannot. The wooden pieces are retained by a very strong adhesive. The screws are only there to hold the bottom piece onto the handle while the glue dried or something. One tempting project might be to remove and re-finish the wood at some point. I decided not to, and left the wood painted gray.

This completes the tear down. I'll include this case picture to show you the quality workmanship that went into this case - you don't see this type of craftsmanship in molded plastic components these days. Even though the press board is a very cheap material, it still took time and effort to assemble this case. Just do not get it wet - as it can and will swell and disintegrate.

Antenna Low, of course, is the coil on the ferrite bar.

The dial scale was loose on the left side. In order to properly secure it, I removed it the rest of the way, only to find that the aluminum panel under the tuning knob was a part of the dial scale, glued to it:

I needed something nice and gooey, with a lot of "sticking power", but not something that would potentially melt into the clear dial. I usually use "Goop" for things like this:

If the following image creeps you out, you are old enough to remember the Andromeda Strain movie. But this is a dent in the speaker grill:

Fortunately, the dent is over an area that is exposed on the rear side:

It was possible to gently bend it out with a wooden probe. The other dents in the speaker grill were not located in areas exposed on the back. The tabs on the aluminum speaker grill are not strong enough to handle even one unbending and re-bending (long hard experience). So any further speaker grill work was not attempted. I am looking for a good source of raw material for speaker grills. There are a lot of places selling 1/8 inch hole stock. That would be ugly here, so I didn't do it. In addition, the original grill has a circular indentation pattern that would be hard to sand, match, or repair. So surface scratches and imperfections were left as-is.

The plastic case was badly oxidized:

Fortunately, there is an excellent product for restoring simulated leather - ArmorAll. I know of this from car dash treatment. In Texas the sun is hot and car dashes take a beating. Good product - but it still took FIVE coatings to restore the case:

One of the chassis standoffs was broken off. It is very obvious somebody has worked as extensively as I have in the past, and their "glue job" did not hold.

The funny thing is, I think that somebody may have been me! I saw more than one 12-675 cross my bench three to four decades ago, and I kind of remember this failure. So - one way or another, a 12-675 I worked on decades ago has come "home". These days, I have found one adhesive left that actually works. The glue sniffing morons have really ruined things for people like me that need glue to be glue and not a slimy or rubbering coating rolling off of plastic. This E-6000 adhesive is as good as you are going to get, but don't tell too many people or the glue sniffing morons will get it banned as well. Use in a well ventilated workspace, and it doesn't take much to make the bond.

My last case issue was a missing foot on the case, which also aligns the case snap. I had an old rubber foot in my parts bin, and all it required was shaving down the shaft:

Properly secured with "Goop", the foot is the same height as the others.

As lovely a radio as this is in its original form, I am not a purist. Every radio in my collection is a working portable, a DX unit made to be the best it can be. I don't go crazy with the mods, but certain ones make sense, and I do those. In case there are purists out there, I retain all original parts should the radio ever come into their hands. I put them in a snack bag and secure them inside the radio so they don't rattle around. That is my one nod to "purity" and "virginity" in radios I restore. Otherwise, they are going to be better than the original!

I learned a long time ago to go as big as you can. The case of the 12-675 has plenty of room for a larger ferrite bar. The only modification required is to notch the AC cord storage box:

And - mounted through the existing brackets, I found I had to do a 180 degree flip on the coil. It still works just fine flipped:

When doing the final alignment, I re-used the original wax for the coil position, and used a hobby craft temperature hot melt glue gun to secure the ferrite to the plastic mounting brackets. Do NOT use regular hot melt - it is hot enough to melt the plastic! Hobby / craft melts at a much lower (and safer) temperature. The glue sticks are white, not yellow, when solid and clear when molten, not yellow. If it is yellow, don't use it on plastic. School of hard knocks - you have been warned!

Why bother?, you ask. AM is mono, this isn't a C-Quam or HD receiver. True, but this picture illustrates the problem:

There are three bands on the plug, and when plugged in, the jack only connects to the tip and the inner two rings are shorted together. This results in audio coming out of just the left side, which is irritating. Radio Shack stores that stock parts sell a replacement jack that will handle modern headphones. It is designed for PC board mounting, but will also work with bare wire:

:

:

And, wired in place of the original:

There is a price to pay. The original scheme of using a flat washer to retain the jack will not work. The threads are too short, and the body of the jack interferes. Fortunately, the hole in the side of the case is square, and the jack fits neatly into it. Our old friend "Goop" to the rescue, and the jack is securely attached to the inside of the hole, and positioned so the plastic well seats snugly against the outside of the case.

Like all vintage transistor radios, the pots are scratchy. You have to remove a bracket to get to them:

I won't go into my shocking restoration technique for pots (and switches) here, but properly restored, they were re-assembled and the bracket re-installed.

More goop on that photo-paper re-creation of the schematic, and I was pretty much done inside - except for alignment:

Every vintage radio has the same issue. The AM dial only goes to 1600 (or 1500 on really old tube units). If you want to tune the top of the dial, it is worth exploring the possibility of re-tuning the radio to receive up to 1700. A radio either will work or won't work up to that frequency. The 12-675 works beautifully - it is well within the trimming range of the radio. I broke out the signal generator, and made up a new scale. After alignment was complete, I taped the new scale over the useless "logging" scale found on most radios:

And that completed my restoration. No "before and after" picture here, because the dial is the only real cosmetic difference, other than a dent I got rid of. The speaker grill was scratched, it still is. Just part of the "character" of the radio - unless I find a suitable replacement.

Getting a bit ahead of myself, selectivity of this radio is not great. I might at some point investigate putting a ceramic filter in the IF chain. I suspect it can be done at C8, but I'd have to try it. I would need to be extremely careful of that dial cord, which crosses the board diagonally. Probably - I can add that to my list of things that will never happen.

I a word - WOW! I think I can truthfully say that I have never owned a good 12-675 before. Even with the old ferrite bar - on initial power up it was amazingly sensitive, much better than I remembered. Definitely on a par with a GE Superadio, which says a lot. I've tried the circuitry of a 12-675 before, last year when I created Frankenradio out of the bare board I had saved. But its performance, even with the same size ferrite, is in no way similar to this radio. The sensitivity is as good as anything I own, easily comparable to a CCrane EP, which is saying a lot, I know. If it were not for poor selectivity, this could easily become my primary DX radio.